丹麦GM

LRN18T/25T Mini Roll Coater

- Product description: LRN18T/25T Mini Roll Coater ,卷对卷柔性薄膜有机太阳能电池印刷设备

Product highlights

Compact platform for production & applied science

Modular system allowing different setups

Proven design tested with multiple processes / in production for more than a decade

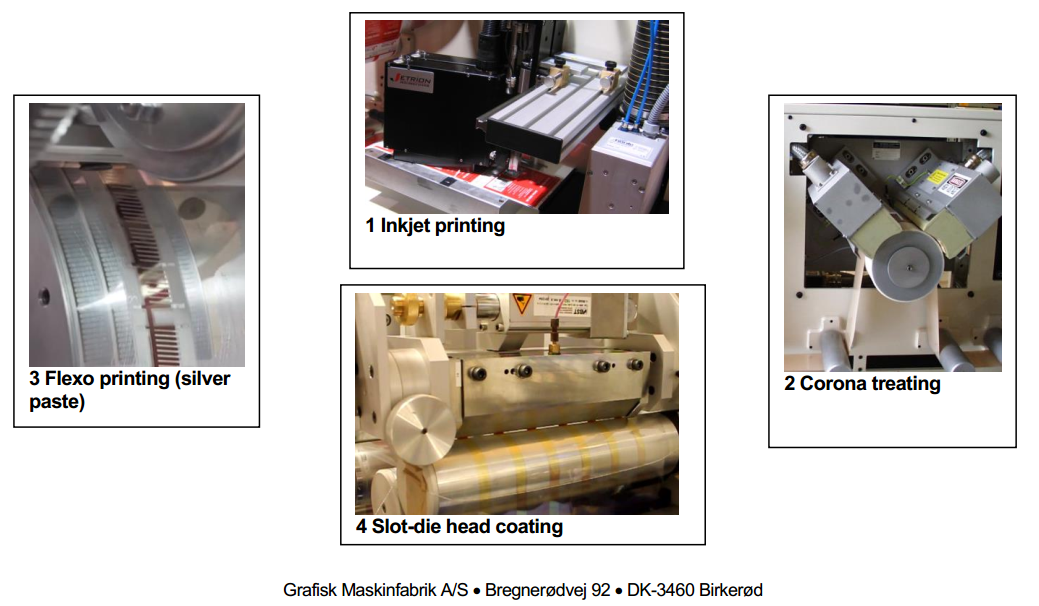

Standard solutions for Inkjet, UV Inkjet & Flexo. Slot-die possible (R2R solar)

Integrated web guide with ultrasonic fork allows for multiple runs on same material (product saving)Extra training and workshops possible for complicated processes

Open platform – PLC code freely available

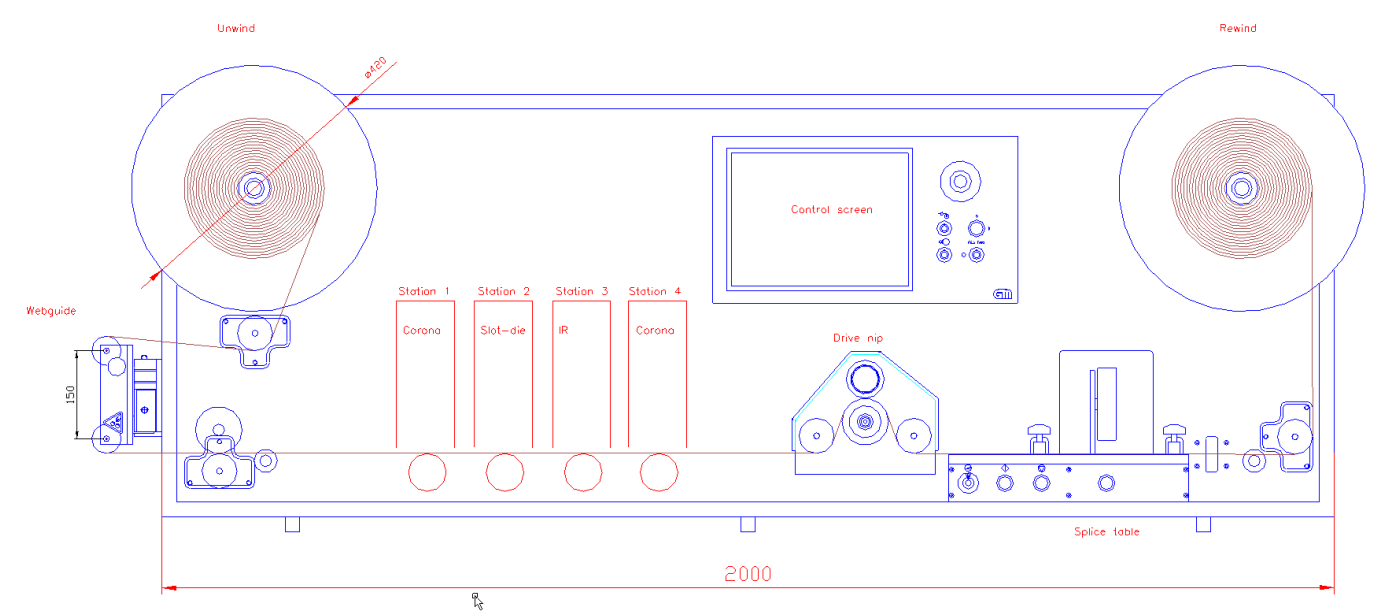

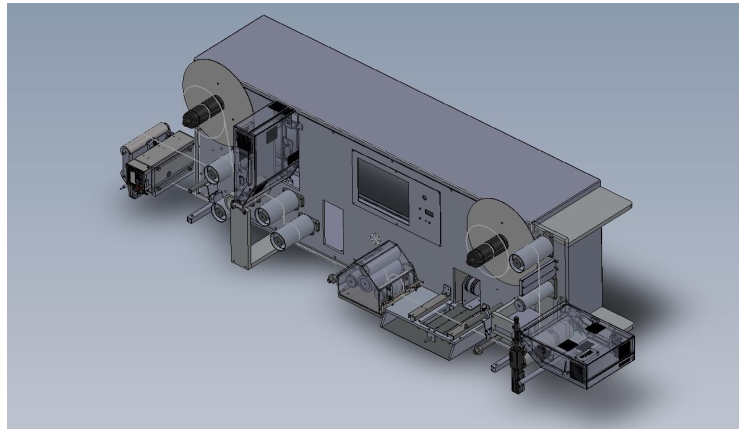

Unit overview

Description

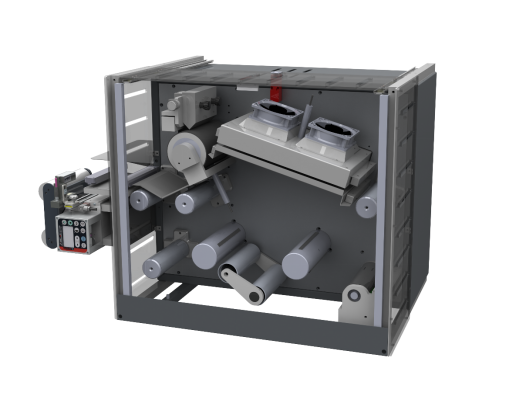

The LRNT mini roll coater from Grafisk maskinfabrik is an easy to use entry platform for multipurpose coating. It features a steady web-drive and a universal platform for mounting different coating heads. The picture above shows a general layout that can be customized to fit a specific application. The unit has an unwind for foil (PET), metalized film or paper. The web is driven forward by the center nip and finally rewound.Typical setup configurations are Inkjet head tester or a OPV solar coater.

The frame of the LRNT is double sided around a station head allowing for heavy heads (slot-die or flexo). Impression wheels for on-rotation silver-paste appliance (solar) can fitted. IR, Hotair and UV curing is supported as standard. Custom- made curing system as LED or VUV are possible on request.

The machine comes in 180mm web width. The small web width ensures minimal substrate waste. At the same time the system can be scaled up by running rolls of Ø300mm (appx. 500-1000m meters) of material. It is an ideal system to mimic large-scale production and the natural step after spin coating. The unit can be used in normal atmosphere or inside a large glove-box. Close up pictures of treatment heads:

Solution examples

Configuration Inkjet R&D: Unwind, Inkjet (UV), UV, Drive, Rewind

On the setup above the LRN18T platform is setup as an UV inkjet printer. The setup verifies the quality of various inkjet heads before they are implemented in large-scale lines. The setup could also be used to re-print a variable layer on a pre- printed web.

Configuration Solar R&D: Unwind, Corona, heated roller, Slot die / flexo stand and rewind.

This setup is good to test solar inks and conductive layers. The machine can be used to make working OPV solar cells. Please note that is can function both as a roll to roll or a single turn roll machine. In single turn mode, only the center roll (see arrow) moves and make a single rotation. When this process works, the process can be scaled up to roll to roll easily by using the unwind and rewinder.

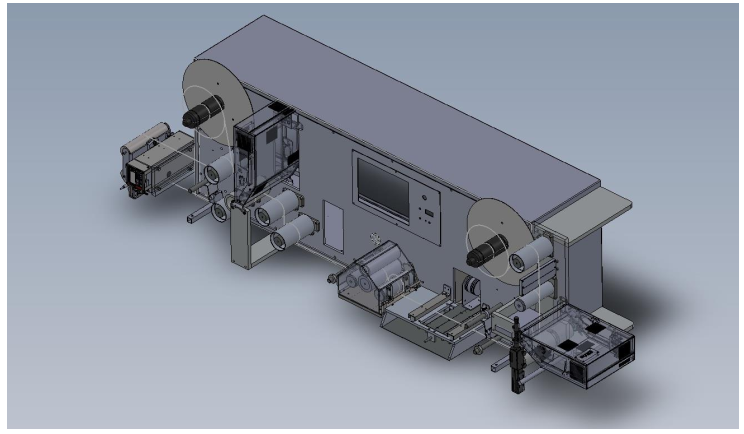

Design example

Grafisk Maskinfabrik has extensive experience in 3D cad designs. Each unit is designed and review by the client in our 3D Solid-works software before it is produced. This step makes it easy to embed client-specific coating heads in the design. The example above shows a variant that has been produced in multiple units. If features two inspection heads and an inkjet for re-printing variable data and verifying it. It is used for production for labels for pharmaceutical products.

Specification

Coating head options: 4 Slots. Possible systems: Inkjet, Flexo, Slot-die, Passive roller (silver paste), Lamination.

Specific data for slot-die head:

Coating width from 10-180mm possible

Head is designed by RISØ-DTU

Dead volume down to 50uLdepending on head type

Mounting: 2-axis movable stage allowing adjustment of height, angle of attack and horizontal position relative to the substrate

Specific data for flexo head:

Conventional 2 roller flexo. Anilox & print roller

Coating width from 2mm-180mm possible.

Head designed by GM

Dead volume 500mL

Wet thickness: 3-30um

Specific data Curing head:

UV upto 150w/cm

VUV upto 10w/cm

Heated drum (0 – 140 ˚C) . Width 180mm.

Large easy to use touch screen.

Dimensions (L x W x H): 2000 x 760/820 x 820 mm

Weight 180/210 kg

Electricity supply 1 x 230 V, 50/60 Hz, Max. 6.0 Amp

Ventilation: End-user is responsible for proper ventilation.

CATEGORIES

CONTACT US

Contact: Adahan

Phone: 13810172901

Tel: 86 10 8499 8901

Email: han@yeadagroup.com

Add: Huilongguan Town, Changping District, Beijing