Products

Laboratory Roll-to-Roll Coater

- Web Width: Up to 200 mm (standard), up to 310 mm (wide models)

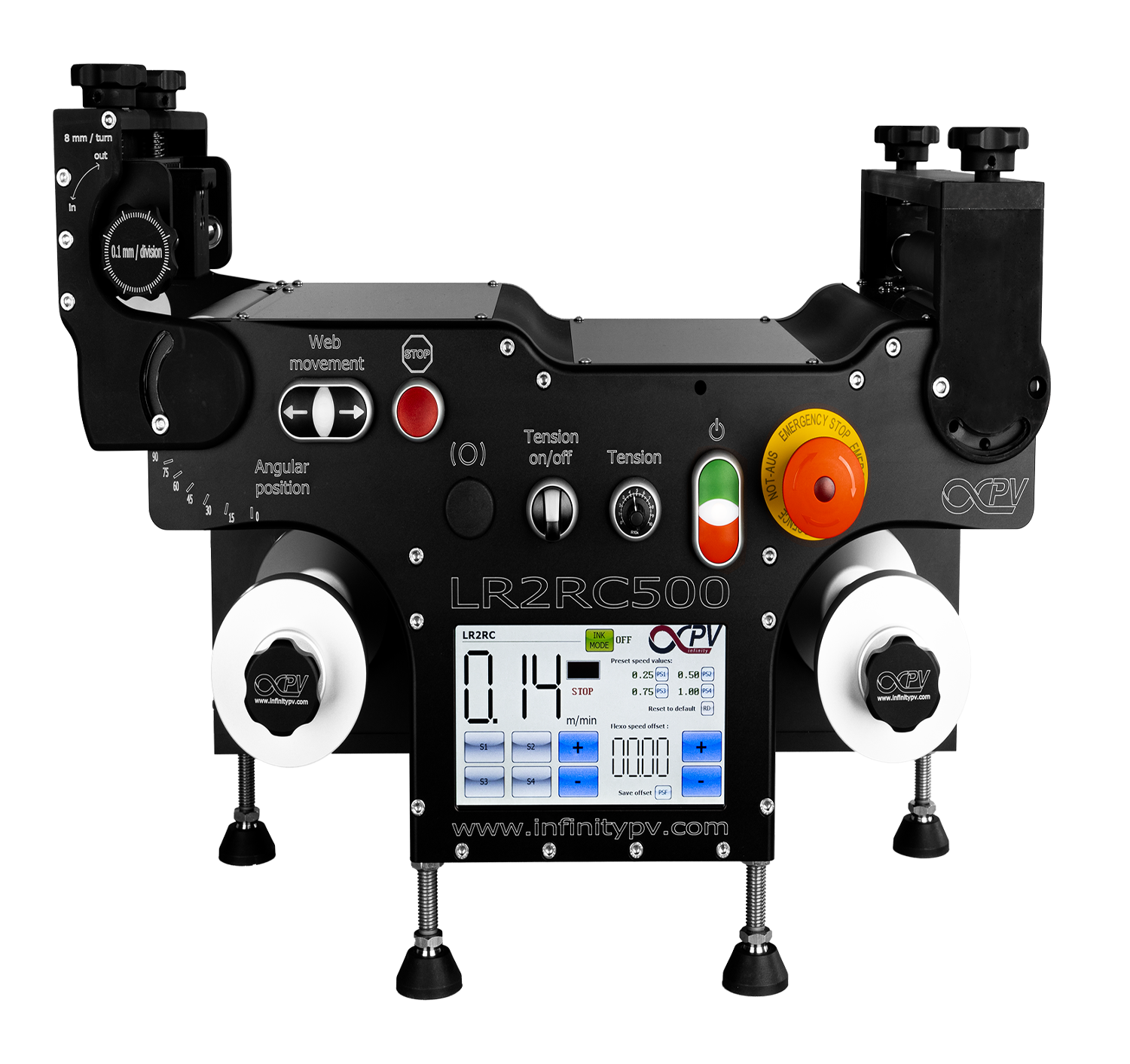

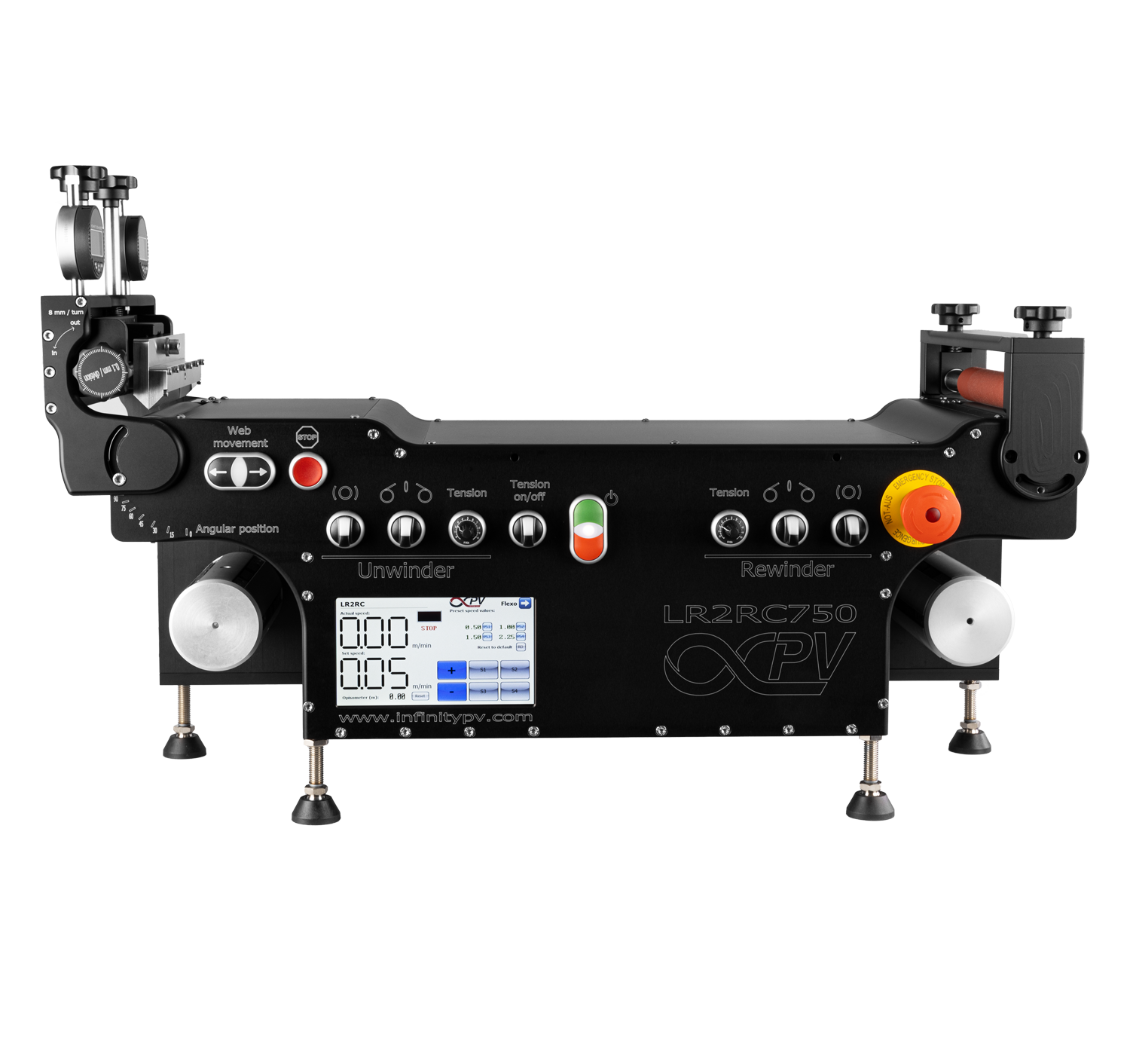

- From 250 mm (LR2RC500) to 1250 mm (LR2RC1500).

- 0.05-2.8 m/min (forward and reverse).

- Product description: A compact high precision laboratory roll-to-roll coating machine that transforms the way functional thin films are printed and coated.

A Compact and High Precision Machine

The Laboratory Roll-to-Roll Coater (LR2RC) is a compact, high-precision machine that transforms the way thin functional films are printed and coated. This versatile system caters to various needs, from laboratory to small pilot-scale production, processing hundreds of meters of foil efficiently.

Modular Customization

The Laboratory Roll-to-Roll Coater's modular design allows users to customize the system according to their specific requirements. Options include selecting the length and width of the unit and choosing from a wide array of accessories, such as printing and coating units, drying and curing systems, foil pretreatment modules, and advanced laminators. This flexibility ensures the Laboratory Roll-to-Roll Coater can fit within existing lab spaces, gloveboxes, or fume hoods without additional infrastructure.

Scalable Efficiency

Providing a complete, turnkey system, the Laboratory Roll-to-Roll Coater bridges the gap between laboratory research and small-scale pilot production. It handles hundreds of meters of foil, making it an economical choice for scaling up production. Advanced slot-die heads, web tension control, and software options guarantee consistent, high-quality results across applications like batteries, fuel cells, printed solar cells, transistors, LEDs, and sensors.

User-Friendly Design

Designed for convenience, the Laboratory Roll-to-Roll Coater features easy-to-remove and reattach components, such as heat and UV stations, enhancing operational efficiency. The system's CE certification and CSA/UL compliance underscore its reliability and adherence to international safety standards.

Build Your Own System Today

Start building your custom thin-film production system today with the Laboratory Roll-to-Roll Coater Customizer. Choose the right platform size and enhance it with a range of accessories like printing units, drying systems, and laminators.

Key Features

-

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

-

Customizable: Choose from a variety of lengths and widths, with numerous accessories available.

-

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

-

Modular Drying/Curing System: Accommodates various drying and curing methods.

-

Software Control Option: Advanced control options for precision and repeatability.

-

Web Tension Control: Ensures consistent quality across runs.

-

CE Certified - CSA/UL Compliant: Meets international safety standards.

Technical Specifications

-

Operating Power: Single phase (240VAC) for smaller models; three-phase (400VAC) for larger models.

-

Drying/Curing Length: From 250 mm (LR2RC500) to 1250 mm (LR2RC1500).

-

Web Width: Up to 200 mm (standard), up to 310 mm (wide models).

-

Web Speed: 0.05-2.8 m/min (forward and reverse).

-

Spindles: Automatic compressed air spindles for 3-inch core diameters, adjustable cones for smaller cores in LR2RC500.

CATEGORIES

CONTACT US

Contact: Adahan

Phone: 13810172901

Tel: 86 10 8499 8901

Email: han@yeadagroup.com

Add: Huilongguan Town, Changping District, Beijing